Precision Machined Components

Saritvat: Making High-Quality CNC Machined Components Easy for Every Industry

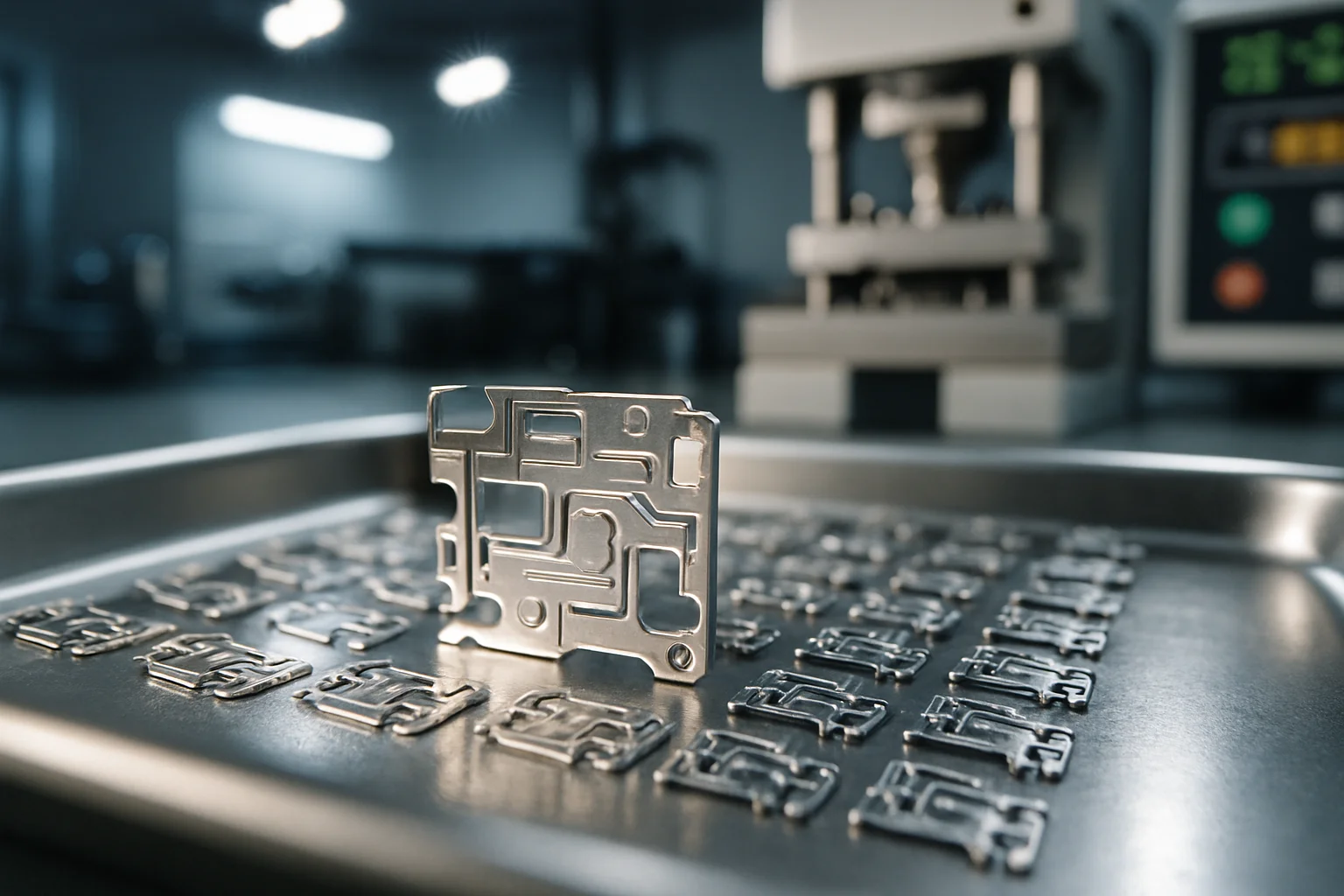

Precision machined components are parts made with advanced CNC machining and fabrication to meet tight tolerances and smooth finishes. These components are essential for industries like aerospace, automotive, electronics, and medical devices where precision and reliability really matter. At Saritvat, we work closely with trusted Vendors, experienced Suppliers, and certified Manufacturers to deliver reliable support for local and nearby clients worldwide.

We use tools like CNC mills, lathes, and wire EDM systems to cut and shape materials with pinpoint accuracy. By making ethical choices in sourcing and process planning, we ensure every client gets quality parts with responsible support. Local Vendors help with scalability and supply continuity, while Manufacturers ensure expectations are consistently exceeded.

Whether it’s metal fabrication using carbon or stainless steel, or including plastics and composites, we often use sheet metal for intricate builds. Vendors and nearby Suppliers love its versatility, and our Support teams use reverse engineering to improve or recreate parts. This helps Manufacturers extend product lifecycles responsibly with the help of nearby machining Vendors and reliable Suppliers.

Our manufacturing process supports both customization and scalability—perfect for small batches or large production runs. With cutting-edge technology like 5-axis CNC, wire EDM, and high-speed machining centers, Saritvat partners with Vendors, Suppliers, and local Support providers to make sure every part meets exact standards while promoting ethical sourcing and empowering local Vendors.

Benefits of Technology

Ultra-high accuracy from CNC machining ensures flawless components delivered by Vendors and nearby Suppliers.

Smooth surface finishes for assemblies and moving parts, backed by experienced Support teams and local Vendors prioritizing quality.

Efficient fabrication methods for low or high-volume production help Suppliers cater to a wide range of clients.

Supports reverse engineering of old or discontinued parts—a value-added service from Support-focused Manufacturers and nearby Vendors.

Works with various materials, including carbon steel and sheet metal, letting Suppliers, Vendors, and Support teams tackle diverse industry needs.

Tight tolerance control for aerospace and medical applications, with ethical decision-making and collaboration between Manufacturers, Suppliers, and Vendors.

Reliable for small, complex parts with nearby Vendor and local Supplier support to meet detailed designs.

Fast prototyping and scalable production through responsive Support networks from Vendors and trusted Manufacturers.

Advanced metal fabrication reduces waste and production time, helping Suppliers and Vendors stay efficient while maintaining ethical practices.

Improves part longevity and performance in tough environments, thanks to teamwork between local Vendors, Suppliers, and Support-oriented Manufacturers.

Industrial Applications

Precision machined components are used across many industries, with Vendors, Suppliers, local Manufacturers, and Support technicians all playing a role:

Aerospace: Engine parts, brackets, housings, and actuators made with precise machining. Vendors and Support teams coordinate to meet aviation-grade standards.

Automotive: Pistons, transmission gears, and brake assemblies crafted with CNC machining, provided by Suppliers and local Vendors working with major Manufacturers.

Medical Devices: Surgical tools and implants needing flawless machining and ethical material sourcing from certified Suppliers and nearby Vendors.

Electronics: Connectors and heat sinks made from precise sheet metal, relying on local Supplier collaboration and Vendor Support.

Defense: Optical components, radars, and fire-control systems machined with wire EDM, supported by nearby Vendors and ethical Support teams.

Industrial Equipment: Pumps, valves, and automation tools fabricated with reliable methods backed by Manufacturers, Vendors, and Support networks.

Energy Sector: Turbine parts and flanges machined from carbon steel, delivered through collaboration with Suppliers, Vendors, and responsible Manufacturers.

Contract Manufacturing: Tailored components for OEMs, supported by local Vendors, responsive Suppliers, and helpful Support teams throughout production.

Materials We Use

We work with a range of materials, chosen based on technical needs and availability from local and nearby Vendors:

Carbon Steel: Strong and wear-resistant, sourced responsibly by Vendors and Suppliers worldwide.

Stainless Steel: Corrosion-resistant, perfect for sterile environments. Manufacturers collaborate with nearby Suppliers for ethical sourcing.

Aluminum: Lightweight and great for aerospace and automotive. Local Vendors help optimize machining and material flow.

Brass & Bronze: Common in electrical and plumbing industries. Suppliers and Vendors coordinate precise machining schedules.

Titanium: Used in medical and defense applications. Requires high-performance manufacturing with responsive Vendor support.

Sheet Metal: Thin, durable, and ideal for intricate parts. Sourced by nearby Suppliers and fabricated ethically by Manufacturers with Vendor collaboration.

Plastics & Composites: Lightweight or electrically insulated components, made accessible by Suppliers, local Vendors, and Support networks.

How Costing Works

Cost depends on factors handled by Vendors, Suppliers, and Support teams working closely with Manufacturers:

Material type affects base price. Ethical sourcing balances cost and availability.

Tolerances influence machining speed and inspections. Planning is done transparently with Manufacturers, Support teams, and Vendors.

Complex processes like wire EDM need collaboration with experienced Suppliers and Support-oriented Vendors.

Batch size and setup time are optimized via CNC programming with guidance from local Vendors and agile Support personnel.

Reverse engineering reduces tooling costs. Vendors and Suppliers value this approach for efficiency and quality.

Contract manufacturing helps reduce overhead and maintain ethical pricing.

Surface treatments and finishes are applied based on client needs, handled by nearby Vendors and local Suppliers.

Lead time and urgency can impact costs. Manufacturers and Support teams work with Vendors and Suppliers to adjust timelines while maintaining trust.

Alternative Technical Suggestions

Depending on your project, Vendors, Suppliers, and Manufacturers may recommend:

Additive Manufacturing: Fast prototyping and lightweight parts, ideal for rapid iterations.

Casting: Cost-effective for large runs, with Supplier input on molds and geometry.

Stamping: Efficient for sheet metal parts, commonly done by local Vendors and Suppliers.

Injection Molding: Ideal for high-volume plastic parts, with Supplier and Vendor support.

Die Cutting: High-speed sheet metal cutting, handled by local Vendors and Support teams.

Manual Machining: Useful for low-volume or custom parts, leveraging Vendor craftsmanship.

Waterjet Cutting: Non-thermal method complementing wire EDM, offered by Vendors, Support teams, and ethical Manufacturers.

FAQs

Q: What are precision machined

components?

A: Parts made using advanced CNC machining and

fabrication, ensuring tight tolerances and

smooth finishes. Vendors and Suppliers deliver

these reliably.

Q: What materials are used?

A: Carbon steel, aluminum, titanium, and sheet

metal. Local Vendors and Suppliers work closely

with Manufacturers to source and process

ethically.

Q: Who benefits from these

components?

A: Aerospace, automotive, medical, electronics,

defense, and automation industries. Vendors,

Suppliers, and Manufacturers provide tailored

solutions.

Q: What does wire EDM do?

A: Creates intricate cuts in hard materials.

Vendors and Support teams use it for

high-precision internal features.

Q: Can old parts be

recreated?

A: Yes, with reverse engineering. Manufacturers,

Vendors, and Support teams can reproduce or

enhance legacy parts.

Q: Why CNC machining?

A: Ensures repeatability, tight tolerances, and

speed. Trusted by local Vendors and Suppliers

for precision work.

Q: What is a contract

manufacturer?

A: Produces parts based on your specs. Local

Vendors and Support-oriented Suppliers provide

full services from prototyping to production.

Q: Why use sheet metal?

A: Lightweight, precise, and versatile. Vendors

and Support teams use it for complex,

quick-to-fabricate designs.

Q: What’s included in the fabrication

method?

A: Milling, turning, EDM, and finishing, with

help from nearby Suppliers, Vendors, and Support

teams.

Q: How does Saritvat support

clients?

A: From prototyping to full production, we work

with Suppliers, Vendors, and Support networks to

ensure project success.

A: By Sea: Asia: 15–20 days, Europe: 25–35 days, North America: 30–40 days, South America: 35–45 days, Middle East: 14–18 days, Africa: 20–28 days, Oceania: 22–30 days

By Air: Asia: 1–3 days, Europe: 3–5 days, North America: 4–6 days, South America: 5–7 days, Middle East: 1–2 days, Africa: 3–5 days, Oceania: 4–6 days