Nylon Machining & Polycarbonate PC Fabrication

SARITVAT Leading the Way in CNC Machining, Nylon Fabrication, and Medical Device Manufacturing with Advanced Thermoplastic Solutions

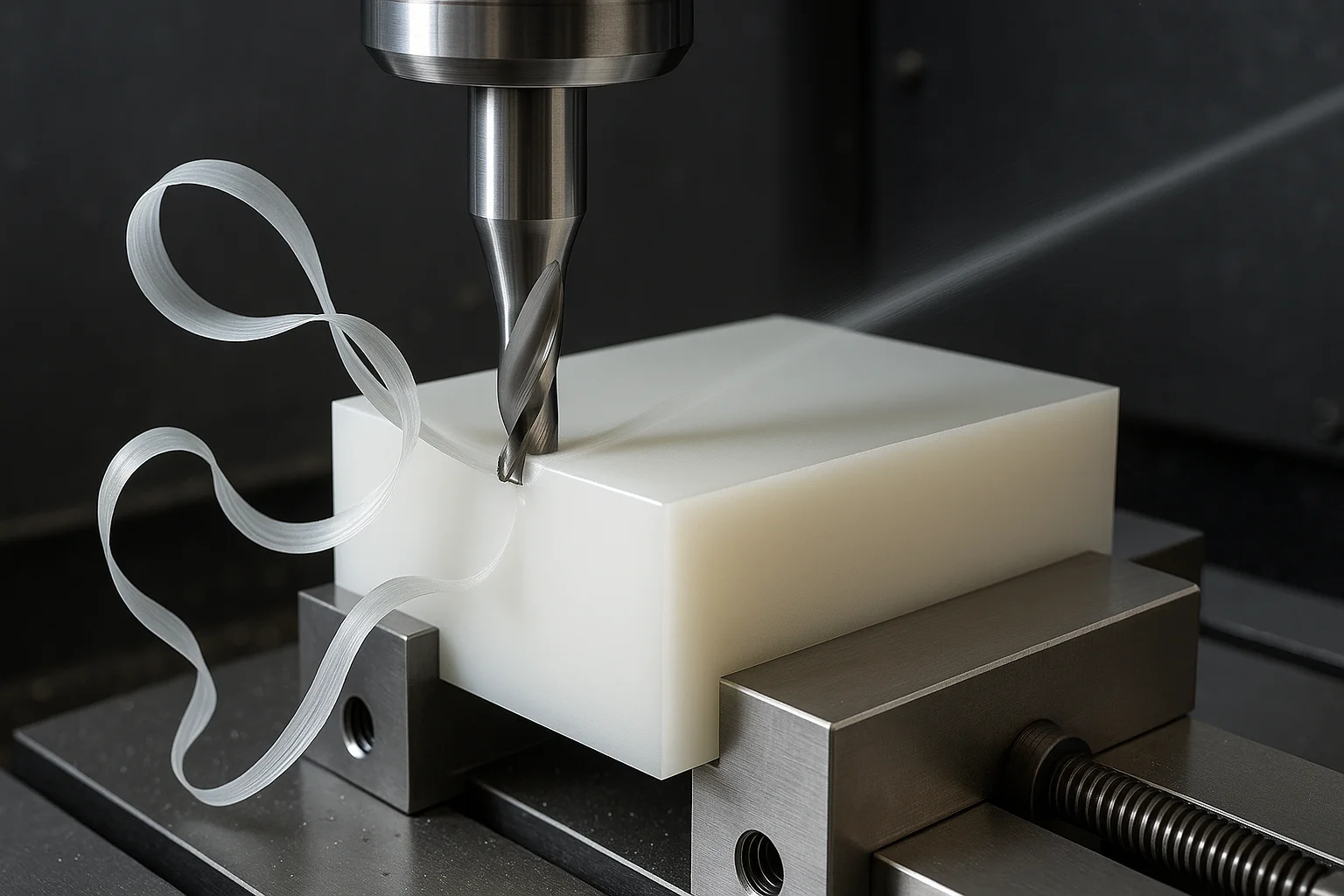

SARITVAT specializes in high-precision CNC machining services, delivering exceptional nylon machining and polycarbonate PC fabrication solutions for diverse industries. We are proud to collaborate with responsible vendors, expert manufacturers, nearby suppliers, and supportive local partners to ensure the highest quality throughout each fabrication cycle. Our advanced manufacturing process capabilities enable the production of complex components with tight tolerances, supported by local and nearby vendor networks that offer streamlined logistical and technical assistance for medical technology, automotive, aerospace, and industrial sectors.

With unmatched expertise in nylon machining, we produce gears, bushings, bearings, and wear-resistant components that demand durability and low friction. These parts are developed through partnerships with trusted vendors and backed by manufacturers who understand how to deliver precise, ethical, and reliable machining support. Our precision machining techniques allow us to handle thermoplastic materials effectively, delivering results enhanced through collaboration with local suppliers and nearby support professionals who align with your long-term product development goals.

Polycarbonate PC is a key material in our manufacturing process, known for its impact resistance, optical clarity, and versatility in medical devices, protective enclosures, and industrial components. We work closely with supportive vendors and certified manufacturers to ensure each fabricated polycarbonate pc part exceeds expectations. Combining polycarbonate pc fabrication with CNC machining enables us to create intricate parts with excellent mechanical properties, with hands-on guidance from ethical local suppliers and nearby manufacturing experts who contribute to smooth implementation across production phases.

Through our tailored nylon fabrication processes, we ensure cost-effective production of lightweight yet robust parts, especially where local support and vendor expertise play an essential role. This approach is designed to empower manufacturers and suppliers who share our commitment to quality, regulatory compliance, and human-centered solutions. Our team is well-versed in medical technology applications, delivering components that meet stringent regulatory standards for medical devices, supported throughout by vendor feedback and local supplier collaboration that guides decisions with empathy and transparency.

Benefits of Nylon Machining & Polycarbonate PC Fabrication

High-precision CNC machining for complex geometries and tight tolerances, enabled through strategic partnerships with experienced manufacturers, local suppliers, and responsive vendors offering reliable technical support.

Nylon machining ensures low-friction, wear-resistant components for dynamic applications, with continual support from vendors and local manufacturers offering design consultation and machining alignment throughout the process.

Polycarbonate PC fabrication provides impact-resistant, lightweight solutions with excellent transparency, made possible by collaborative efforts among nearby suppliers, ethical vendors, and qualified manufacturers focused on functionality and safety.

Thermoplastic materials like nylon and polycarbonate are ideal for medical devices requiring biocompatibility and chemical resistance, often sourced through certified suppliers, trusted vendors, and manufacturers with local support experience.

Precision machining techniques reduce material wastage and enhance surface finish quality, aligning with sustainability goals set by local vendors and supported by manufacturers and nearby supplier strategies.

Manufacturing process optimization ensures cost-effective solutions for both prototypes and high-volume production, benefiting from input by supportive vendors, supplier audits, and feedback loops with nearby manufacturers and teams.

Nylon fabrication allows for customized components in automotive, medical, and industrial sectors, developed with guidance from suppliers, vendors, and manufacturers offering helpful support systems within local networks.

Expertise in product development, from design validation to production scaling, is strengthened through relationships with local suppliers, nearby vendors, and ethical manufacturers who provide timely support and decision-making assistance.

Industrial Applications and Use Cases

Medical Devices: Custom surgical instruments, implants, and housings utilizing nylon machining and polycarbonate pc fabrication for biocompatibility and durability, supported by experienced vendors, suppliers, and local manufacturing teams.

Automotive: Gears, bushings, and precision machined components where low friction and impact resistance are critical, with development led by vendors and suppliers offering nearby machining support and manufacturer input.

Aerospace: Lightweight nylon fabrication for structural parts, seals, and brackets exposed to harsh environments, designed in coordination with ethical suppliers, vendors, and local manufacturer collaboration hubs.

Consumer Electronics: Transparent polycarbonate enclosures and precision machined connectors for devices, crafted through relationships with local vendors and suppliers who understand fast-paced development and nearby service access.

Industrial Machinery: Nylon machining of gears, pulleys, and wear strips ensuring high performance and longevity, optimized through vendor consultation, supplier tooling alignment, and manufacturer-backed local support.

Packaging: Polycarbonate pc components used in protective packaging solutions manufactured with input from ethical suppliers, responsive vendors, and manufacturers situated within nearby support zones.

Medical Technology: Components requiring precision machining and chemical resistance for sterilization and durability, developed through partnerships with suppliers and vendors, with strong manufacturer backing and local guidance.

Custom Manufacturing: Nylon fabrication for specialized parts in food processing and laboratory equipment, produced through collaboration between supportive vendors, local suppliers, and nearby manufacturers who align with industry needs.

Materials Used in Technology

Nylon 6 & Nylon 66: High strength, wear resistance, and excellent machinability for precision components provided by trusted suppliers and manufactured with support from local vendor operations and nearby machine specialists.

Glass-Filled Nylon: Enhanced stiffness and thermal stability for high-stress applications, supported by vendors and manufacturers offering local sourcing and responsive supplier-based fabrication advice.

Polycarbonate PC: Transparent, impact-resistant thermoplastic ideal for protective enclosures and medical devices, fabricated through supplier-certified facilities and vendors with nearby fabrication expertise.

Thermoplastic Materials: Broad selection including PEEK, ABS, and Delrin for specialized applications, all managed through ethical vendor distribution and supplier support teams based in local manufacturing environments.

Medical-Grade Polymers: Biocompatible materials suitable for medical technology and devices, provided through vendors and suppliers backed by manufacturers who understand the needs of nearby healthcare markets.

How Costing Works

Costing for CNC machining and nylon fabrication depends on part complexity, material selection, batch size, and finishing requirements. SARITVAT collaborates closely with vendors, manufacturers, and local suppliers to provide ethical costing strategies supported by nearby logistics and technical networks.

We optimize the manufacturing process by leveraging advanced precision machining techniques, ensuring minimal material wastage and reduced cycle times. These efforts are made possible by collaboration with supplier-led initiatives and vendor support structures located within nearby production regions.

For polycarbonate pc fabrication, costs are determined by thickness, machining tolerances, and surface finishing needs, which are influenced by supplier material recommendations, vendor capabilities, and manufacturer-backed support guidance.

Medical device components undergo rigorous quality control, which is factored into project costing with full transparency. This transparency is ensured by responsible vendors, nearby supplier feedback, and ethical manufacturers who align on high standards and local compliance strategies.

Our product development support ensures design-for-manufacturing, enhancing cost efficiency across all production stages, supported by vendors, local suppliers, and manufacturers who work together to offer human-driven value without compromising quality.

Alternative Technical Suggestions

Injection Molding: Suitable for high-volume production of thermoplastic materials but less flexible for design changes. Vendors and suppliers offer scalable manufacturing solutions with support from nearby manufacturer partners.

3D Printing: Ideal for rapid prototyping and custom product development in medical technology. Local vendors and supplier labs offer flexible support aligned with nearby production needs and ethical decision-making standards.

Laser Cutting: Used for sheet polycarbonate pc components requiring intricate cutouts, supported by specialized manufacturers and nearby vendors with supplier-assisted cutting and design systems.

Die Cutting: Suitable for mass-producing flat nylon and polycarbonate gaskets and seals, provided by vendor-led supply chains with support from manufacturers and nearby tooling suppliers.

Precision Casting: Alternative for complex geometries where CNC machining is not feasible, with vendor and supplier collaboration on prototype design and nearby production scaling options.

FAQs

Q: What is CNC Machining and how does

SARITVAT apply it in Nylon

Fabrication?

A: CNC machining is a subtractive manufacturing

process where computer-controlled tools remove

material from a workpiece to achieve precise

dimensions. SARITVAT utilizes CNC machining for

nylon fabrication, producing high-quality

components with superior surface finishes and

tight tolerances. This is achieved with

vendor-certified tools, supplier-approved

materials, and support from local and nearby

manufacturers.

Q: How does Polycarbonate PC Fabrication

benefit medical devices?

A: Polycarbonate pc fabrication offers

lightweight, durable, and biocompatible

solutions essential for medical devices,

providing excellent impact resistance,

sterilization compatibility, and optical clarity

for housings and covers. These advantages are

enabled through local supplier material

knowledge, nearby vendor support, and guidance

from trusted manufacturers.

Q: What makes nylon machining suitable

for industrial applications?

A: Nylon machining delivers components with high

wear resistance, low friction, and excellent

dimensional stability, making it ideal for

gears, bearings, and structural parts in

automotive, aerospace, and manufacturing

sectors. Our suppliers and vendors offer ethical

support and manufacturers in nearby facilities

ensure consistent execution.

Q: Can SARITVAT support custom product

development in medical

technology?

A: Yes, SARITVAT offers end-to-end product

development support, including material

selection, prototyping, precision machining, and

production scaling for medical technology

applications, all guided by ethical vendors,

certified suppliers, and nearby manufacturer

resources.

Q: What types of thermoplastic materials

does SARITVAT specialize in

machining?

A: SARITVAT specializes in machining a wide

range of thermoplastic materials, including

nylon, polycarbonate pc, PEEK, ABS, and more.

Our suppliers and vendors provide support

through local and nearby sourcing networks that

ensure consistent material quality and

availability.

Q: How does precision machining improve

component quality?

A: Precision machining ensures components meet

exact dimensional tolerances, delivering

superior fit, function, and surface finish.

These results are achieved through supplier

input, vendor innovation, and manufacturer

support that prioritizes local production

excellence.

Q: What are the advantages of nylon

fabrication over metal

components?

A: Nylon fabrication offers benefits like

reduced weight, lower friction, chemical

resistance, and cost-effectiveness compared to

metal components. With support from local

vendors, manufacturers, and nearby suppliers, we

help clients transition to thermoplastics with

confidence.

Q: How does SARITVAT manage the

manufacturing process to maintain cost

efficiency?

A: SARITVAT optimizes the manufacturing process

by leveraging advanced CNC machining,

material-efficient fabrication techniques, and

streamlined workflows, ensuring competitive

pricing without compromising quality. These

optimizations are supported by vendor

coordination and supplier-backed decisions

involving nearby experts.

Q: Can polycarbonate pc fabrication be

combined with CNC machining for complex

parts?

A: Absolutely, combining polycarbonate pc

fabrication with CNC machining enables the

production of complex, high-precision components

suited for protective enclosures, medical

housings, and industrial applications. Local

vendors and nearby manufacturers enable

efficient integration of both technologies.

Q: Why choose SARITVAT for nylon

machining and polycarbonate pc fabrication

services?

A: SARITVAT offers unmatched expertise in CNC

machining, nylon fabrication, and product

development, delivering high-quality,

cost-effective solutions across automotive,

medical technology, and industrial sectors. We

work closely with vendors, local suppliers, and

nearby manufacturers to ensure every project is

supported with empathy, ethics, and human-like

care.

Nylon Machining & Polycarbonate PC Fabrication

SARITVAT Leading the Way in CNC Machining, Nylon Fabrication, and Medical Device Manufacturing with Advanced Thermoplastic Solutions

SARITVAT specializes in high-precision CNC machining services, delivering exceptional nylon machining and polycarbonate PC fabrication solutions for diverse industries. We are proud to collaborate with responsible vendors, expert manufacturers, nearby suppliers, and supportive local partners to ensure the highest quality throughout each fabrication cycle. Our advanced manufacturing process capabilities enable the production of complex components with tight tolerances, supported by local and nearby vendor networks that offer streamlined logistical and technical assistance for medical technology, automotive, aerospace, and industrial sectors.

With unmatched expertise in nylon machining, we produce gears, bushings, bearings, and wear-resistant components that demand durability and low friction. These parts are developed through partnerships with trusted vendors and backed by manufacturers who understand how to deliver precise, ethical, and reliable machining support. Our precision machining techniques allow us to handle thermoplastic materials effectively, delivering results enhanced through collaboration with local suppliers and nearby support professionals who align with your long-term product development goals.

Polycarbonate PC is a key material in our manufacturing process, known for its impact resistance, optical clarity, and versatility in medical devices, protective enclosures, and industrial components. We work closely with supportive vendors and certified manufacturers to ensure each fabricated polycarbonate pc part exceeds expectations. Combining polycarbonate pc fabrication with CNC machining enables us to create intricate parts with excellent mechanical properties, with hands-on guidance from ethical local suppliers and nearby manufacturing experts who contribute to smooth implementation across production phases.

Through our tailored nylon fabrication processes, we ensure cost-effective production of lightweight yet robust parts, especially where local support and vendor expertise play an essential role. This approach is designed to empower manufacturers and suppliers who share our commitment to quality, regulatory compliance, and human-centered solutions. Our team is well-versed in medical technology applications, delivering components that meet stringent regulatory standards for medical devices, supported throughout by vendor feedback and local supplier collaboration that guides decisions with empathy and transparency.

Benefits of Nylon Machining & Polycarbonate PC Fabrication

High-precision CNC machining for complex geometries and tight tolerances, enabled through strategic partnerships with experienced manufacturers, local suppliers, and responsive vendors offering reliable technical support.

Nylon machining ensures low-friction, wear-resistant components for dynamic applications, with continual support from vendors and local manufacturers offering design consultation and machining alignment throughout the process.

Polycarbonate PC fabrication provides impact-resistant, lightweight solutions with excellent transparency, made possible by collaborative efforts among nearby suppliers, ethical vendors, and qualified manufacturers focused on functionality and safety.

Thermoplastic materials like nylon and polycarbonate are ideal for medical devices requiring biocompatibility and chemical resistance, often sourced through certified suppliers, trusted vendors, and manufacturers with local support experience.

Precision machining techniques reduce material wastage and enhance surface finish quality, aligning with sustainability goals set by local vendors and supported by manufacturers and nearby supplier strategies.

Manufacturing process optimization ensures cost-effective solutions for both prototypes and high-volume production, benefiting from input by supportive vendors, supplier audits, and feedback loops with nearby manufacturers and teams.

Nylon fabrication allows for customized components in automotive, medical, and industrial sectors, developed with guidance from suppliers, vendors, and manufacturers offering helpful support systems within local networks.

Expertise in product development, from design validation to production scaling, is strengthened through relationships with local suppliers, nearby vendors, and ethical manufacturers who provide timely support and decision-making assistance.

Industrial Applications and Use Cases

Medical Devices: Custom surgical instruments, implants, and housings utilizing nylon machining and polycarbonate pc fabrication for biocompatibility and durability, supported by experienced vendors, suppliers, and local manufacturing teams.

Automotive: Gears, bushings, and precision machined components where low friction and impact resistance are critical, with development led by vendors and suppliers offering nearby machining support and manufacturer input.

Aerospace: Lightweight nylon fabrication for structural parts, seals, and brackets exposed to harsh environments, designed in coordination with ethical suppliers, vendors, and local manufacturer collaboration hubs.

Consumer Electronics: Transparent polycarbonate enclosures and precision machined connectors for devices, crafted through relationships with local vendors and suppliers who understand fast-paced development and nearby service access.

Industrial Machinery: Nylon machining of gears, pulleys, and wear strips ensuring high performance and longevity, optimized through vendor consultation, supplier tooling alignment, and manufacturer-backed local support.

Packaging: Polycarbonate pc components used in protective packaging solutions manufactured with input from ethical suppliers, responsive vendors, and manufacturers situated within nearby support zones.

Medical Technology: Components requiring precision machining and chemical resistance for sterilization and durability, developed through partnerships with suppliers and vendors, with strong manufacturer backing and local guidance.

Custom Manufacturing: Nylon fabrication for specialized parts in food processing and laboratory equipment, produced through collaboration between supportive vendors, local suppliers, and nearby manufacturers who align with industry needs.

Materials Used in Technology

Nylon 6 & Nylon 66: High strength, wear resistance, and excellent machinability for precision components provided by trusted suppliers and manufactured with support from local vendor operations and nearby machine specialists.

Glass-Filled Nylon: Enhanced stiffness and thermal stability for high-stress applications, supported by vendors and manufacturers offering local sourcing and responsive supplier-based fabrication advice.

Polycarbonate PC: Transparent, impact-resistant thermoplastic ideal for protective enclosures and medical devices, fabricated through supplier-certified facilities and vendors with nearby fabrication expertise.

Thermoplastic Materials: Broad selection including PEEK, ABS, and Delrin for specialized applications, all managed through ethical vendor distribution and supplier support teams based in local manufacturing environments.

Medical-Grade Polymers: Biocompatible materials suitable for medical technology and devices, provided through vendors and suppliers backed by manufacturers who understand the needs of nearby healthcare markets.

How Costing Works

Costing for CNC machining and nylon fabrication depends on part complexity, material selection, batch size, and finishing requirements. SARITVAT collaborates closely with vendors, manufacturers, and local suppliers to provide ethical costing strategies supported by nearby logistics and technical networks.

We optimize the manufacturing process by leveraging advanced precision machining techniques, ensuring minimal material wastage and reduced cycle times. These efforts are made possible by collaboration with supplier-led initiatives and vendor support structures located within nearby production regions.

For polycarbonate pc fabrication, costs are determined by thickness, machining tolerances, and surface finishing needs, which are influenced by supplier material recommendations, vendor capabilities, and manufacturer-backed support guidance.

Medical device components undergo rigorous quality control, which is factored into project costing with full transparency. This transparency is ensured by responsible vendors, nearby supplier feedback, and ethical manufacturers who align on high standards and local compliance strategies.

Our product development support ensures design-for-manufacturing, enhancing cost efficiency across all production stages, supported by vendors, local suppliers, and manufacturers who work together to offer human-driven value without compromising quality.

Alternative Technical Suggestions

Injection Molding: Suitable for high-volume production of thermoplastic materials but less flexible for design changes. Vendors and suppliers offer scalable manufacturing solutions with support from nearby manufacturer partners.

3D Printing: Ideal for rapid prototyping and custom product development in medical technology. Local vendors and supplier labs offer flexible support aligned with nearby production needs and ethical decision-making standards.

Laser Cutting: Used for sheet polycarbonate pc components requiring intricate cutouts, supported by specialized manufacturers and nearby vendors with supplier-assisted cutting and design systems.

Die Cutting: Suitable for mass-producing flat nylon and polycarbonate gaskets and seals, provided by vendor-led supply chains with support from manufacturers and nearby tooling suppliers.

Precision Casting: Alternative for complex geometries where CNC machining is not feasible, with vendor and supplier collaboration on prototype design and nearby production scaling options.

FAQs

Q: What is CNC Machining and how does

SARITVAT apply it in Nylon

Fabrication?

A: CNC machining is a subtractive manufacturing

process where computer-controlled tools remove

material from a workpiece to achieve precise

dimensions. SARITVAT utilizes CNC machining for

nylon fabrication, producing high-quality

components with superior surface finishes and

tight tolerances. This is achieved with

vendor-certified tools, supplier-approved

materials, and support from local and nearby

manufacturers.

Q: How does Polycarbonate PC Fabrication

benefit medical devices?

A: Polycarbonate pc fabrication offers

lightweight, durable, and biocompatible

solutions essential for medical devices,

providing excellent impact resistance,

sterilization compatibility, and optical clarity

for housings and covers. These advantages are

enabled through local supplier material

knowledge, nearby vendor support, and guidance

from trusted manufacturers.

Q: What makes nylon machining suitable

for industrial applications?

A: Nylon machining delivers components with high

wear resistance, low friction, and excellent

dimensional stability, making it ideal for

gears, bearings, and structural parts in

automotive, aerospace, and manufacturing

sectors. Our suppliers and vendors offer ethical

support and manufacturers in nearby facilities

ensure consistent execution.

Q: Can SARITVAT support custom product

development in medical

technology?

A: Yes, SARITVAT offers end-to-end product

development support, including material

selection, prototyping, precision machining, and

production scaling for medical technology

applications, all guided by ethical vendors,

certified suppliers, and nearby manufacturer

resources.

Q: What types of thermoplastic materials

does SARITVAT specialize in

machining?

A: SARITVAT specializes in machining a wide

range of thermoplastic materials, including

nylon, polycarbonate pc, PEEK, ABS, and more.

Our suppliers and vendors provide support

through local and nearby sourcing networks that

ensure consistent material quality and

availability.

Q: How does precision machining improve

component quality?

A: Precision machining ensures components meet

exact dimensional tolerances, delivering

superior fit, function, and surface finish.

These results are achieved through supplier

input, vendor innovation, and manufacturer

support that prioritizes local production

excellence.

Q: What are the advantages of nylon

fabrication over metal

components?

A: Nylon fabrication offers benefits like

reduced weight, lower friction, chemical

resistance, and cost-effectiveness compared to

metal components. With support from local

vendors, manufacturers, and nearby suppliers, we

help clients transition to thermoplastics with

confidence.

Q: How does SARITVAT manage the

manufacturing process to maintain cost

efficiency?

A: SARITVAT optimizes the manufacturing process

by leveraging advanced CNC machining,

material-efficient fabrication techniques, and

streamlined workflows, ensuring competitive

pricing without compromising quality. These

optimizations are supported by vendor

coordination and supplier-backed decisions

involving nearby experts.

Q: Can polycarbonate pc fabrication be

combined with CNC machining for complex

parts?

A: Absolutely, combining polycarbonate pc

fabrication with CNC machining enables the

production of complex, high-precision components

suited for protective enclosures, medical

housings, and industrial applications. Local

vendors and nearby manufacturers enable

efficient integration of both technologies.

Q: Why choose SARITVAT for nylon

machining and polycarbonate pc fabrication

services?

A: SARITVAT offers unmatched expertise in CNC

machining, nylon fabrication, and product

development, delivering high-quality,

cost-effective solutions across automotive,

medical technology, and industrial sectors. We

work closely with vendors, local suppliers, and

nearby manufacturers to ensure every project is

supported with empathy, ethics, and human-like

care.

A: By Sea: Asia: 15–20 days, Europe: 25–35 days, North America: 30–40 days, South America: 35–45 days, Middle East: 14–18 days, Africa: 20–28 days, Oceania: 22–30 days

By Air: Asia: 1–3 days, Europe: 3–5 days, North America: 4–6 days, South America: 5–7 days, Middle East: 1–2 days, Africa: 3–5 days, Oceania: 4–6 days