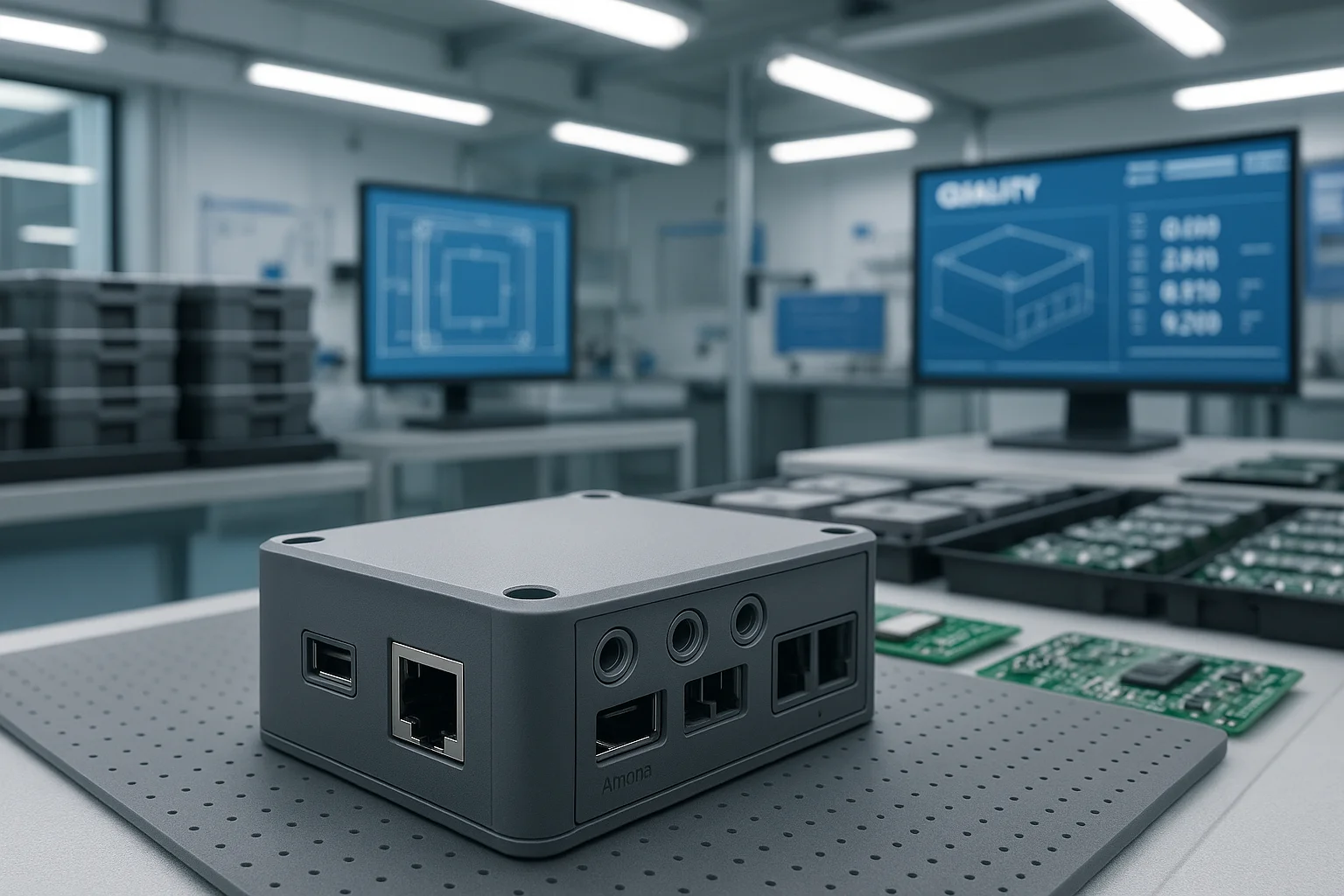

IoT Enclosure

SARITVAT Bringing Better Quality with Smart Finishing & Surface Treatment

At SARITVAT, we design and manufacture IoT enclosures by combining smart product design, advanced injection molding, and flexible contract manufacturing. Our ABS plastic enclosures deliver durability, protection, and design flexibility, ensuring every local or global deployment gets consistent quality. We work closely with our Suppliers, Vendors, and Manufacturers networks, making sure service and support are smooth and responsive.

Our scalable molding services are trusted by teams who value reliable production and practical guidance. From concept to production, we help both nearby businesses and large international projects with clear communication and ethical practices. Whether it’s IP-rated outdoor casings or intricate IoT PCB housings, our plastic solutions are built to meet industry standards and make life easier for Suppliers and Vendors alike.

With laser engraving, we can personalize smart casings for local and global brands. Our high-precision molding ensures tight tolerances and premium finishes. Every enclosure we deliver supports diverse systems, giving flexibility and long-term support, while nearby coordination helps Suppliers and Vendors move from prototype to production confidently.

Benefits of SARITVAT Finishing Techniques

We specialize in creating enclosures with reliable injection molding processes, especially using ABS plastic for strength, temperature resistance, and durability. SARITVAT delivers precision at every step, giving Manufacturers peace of mind even on large-volume projects, while keeping Suppliers informed throughout.

We also integrate essential features like IP-rated sealing and PCB housing into our designs. Whether you’re a nearby Supplier needing fast turnaround or a global Vendor expecting consistent quality, our solutions combine performance, ethical manufacturing, and human-like support you can trust.

Thanks to our refined molding services, every unit—from standard to fully custom enclosures—meets branding, functional, and regulatory requirements. Our white-label capabilities and dedication to support make us a preferred partner for Suppliers, Vendors, and Manufacturers in local and global IoT markets.

Industrial Applications and Use Cases

Consumer IoT: Smart thermostat, hub, and speaker housings using ABS plastic, helping nearby Vendors with smooth local rollouts and clear documentation for Suppliers.

Medical Devices: Compact diagnostic and wearable enclosures with IP-rated protection, supporting local clinics and larger hospital Suppliers with clear, ethical guidance.

Industrial Automation: Durable enclosures for factory environments, helping Manufacturers maintain critical operations with responsive Supplier coordination.

Telecom: White-label casings for routers, modems, and connectivity devices, ensuring smooth delivery for local and global Vendors and Suppliers.

Smart Agriculture: Weatherproof enclosures for IoT devices, supporting Vendors in rural areas and nearby farms with ethical, cost-conscious choices.

Retail & POS: Sleek ABS enclosures with laser engraving for terminals and kiosks, simplifying local rollouts and Supplier decisions.

Home Automation: Customized enclosures for smart devices, aligning Supplier needs with local installation and Vendor support.

Automotive IoT: Compact IP-rated enclosures for vehicle diagnostics and fleet tracking, supporting both nearby and distant Suppliers with structured guidance.

Materials and Technologies Used

ABS Plastic: Strong, moldable, and reliable, perfect for IoT enclosure manufacturing with ethical sourcing and nearby availability.

Injection Molding: The backbone of custom IoT enclosures, ensuring consistency and clear Supplier coordination during local support phases.

Laser Engraving: Adds branding, labels, or IDs for local and global recognition, with practical Supplier documentation.

Sealed IP-Rated Enclosures: Dust- and waterproof designs, easing approvals for Manufacturers with nearby testing support.

Smart Device Systems: Integrates PCB housing and optimized design for confident decision-making by Vendors and Suppliers.

White-Label Solutions: Ready-to-brand enclosures at scale, supporting local inventory and nearby coordination.

Automated Assembly Lines: Efficient production for Vendors and Manufacturers, combining support with data-driven decision-making.

Custom Molding Services: Rapid prototyping and large-batch production with precise design fidelity, helping balance local speed and global scale.

Costing in Finishing Techniques

Pricing depends on material choice, product complexity, IP-rated standards, and production volume. SARITVAT’s contract manufacturing ensures cost-effective scaling for both local Suppliers and global Vendors, with ethical transparency and support at every step.

We reduce costs using advanced injection molding, streamlined assembly, and precise plastic molding. Automated laser engraving improves accuracy and productivity for Manufacturers near and far, while Support helps Suppliers make clear, informed decisions.

IoT PCB housing and smart-device integrations are planned to maximize material efficiency and minimize tooling costs. Our support covers both custom and standard products, making us a reliable partner for local pilots and global ramp-ups alike.

Alternative Technical Innovations

Dual-Shot Molding: Multi-material molding with strong bonding, trusted by Suppliers and supported by ethical practices.

Silicone Overmolding: Combines rubber and ABS for resilient enclosures with decision-ready designs.

Laser Surface Texturing: Improves grip and appearance, backed by Supplier training for local demos.

High-Speed Assembly Lines: Automates PCB housing placement, simplifying coordination and boosting efficiency.

Modular Enclosure Systems: Adaptable designs with support to help Vendors and Suppliers make ethical decisions quickly.

Custom IP-Rated Vents: Ensures airflow in sealed devices with nearby testing support for easier Supplier approvals.

Rapid White-Label Tooling: Low-lead-time molds for quick market entry, with Vendors collaboration and ethical traceability.

Automated Product Validation: AI-assisted checks for manufacturability at scale, giving Suppliers and Manufacturers practical insights.

FAQs

Q: What are IoT Enclosure Techniques in Manufacturing?

A: Techniques include injection molding, ABS selection, laser engraving, and contract manufacturing for robust, IP-rated casings. SARITVAT provides clear support for Vendors, Suppliers, and Manufacturers locally and internationally.

Q: How does SARITVAT ensure corrosion resistance?

A: High-grade ABS and precision molding produce sealed, IP-rated enclosures. Our solutions help Suppliers and Manufacturers maintain product longevity with practical support.

Q: What is the role of contract manufacturing?

A: Covers product design, tooling, and assembly, helping Vendors and Suppliers scale production while maintaining ethical and decision-ready practices.

Q: How does injection molding improve surface treatment?

A: Provides smooth finishes and precise dimensions, ideal for branding via laser engraving. Support teams guide Vendors on optimal finishes.

Q: Which industries benefit most?

A: Telecom, home automation, healthcare, retail, and automotive sectors rely on IP-rated ABS enclosures. We support local Vendors and global Suppliers with ethical guidance.

Q: Can SARITVAT handle urgent projects with local Suppliers?

A: Yes, we work closely with local and nearby Suppliers for fast turnarounds, providing empathetic, clear, and timely support.

Q: How do Manufacturers benefit from SARITVAT’s services?

A: They get consistent quality, scalable production, and design flexibility. Support and coordination help Suppliers move forward confidently.

Q: Does SARITVAT provide after-sales support?

A: Absolutely, continuous support ensures long-term product performance with local and nearby service options.

Q: Are custom designs available?

A: Yes, we work with each Vendor and Supplier to create tailored IoT enclosure solutions with practical guidance and ethical transparency.

Q: What makes SARITVAT different?

A: Ethical manufacturing, local and global collaboration, and dedicated support set us apart, delivering enclosures that meet both technical and business needs.

Q: What are the maximum estimated shipping times from the factory to global regions for Brazing parts via sea and air?A: By Sea: Asia: 15–20 days, Europe: 25–35 days, North America: 30–40 days, South America: 35–45 days, Middle East: 14–18 days, Africa: 20–28 days, Oceania: 22–30 days

By Air: Asia: 1–3 days, Europe: 3–5 days, North America: 4–6 days, South America: 5–7 days, Middle East: 1–2 days, Africa: 3–5 days, Oceania: 4–6 days